| Brands | Yuzuki |

|---|---|

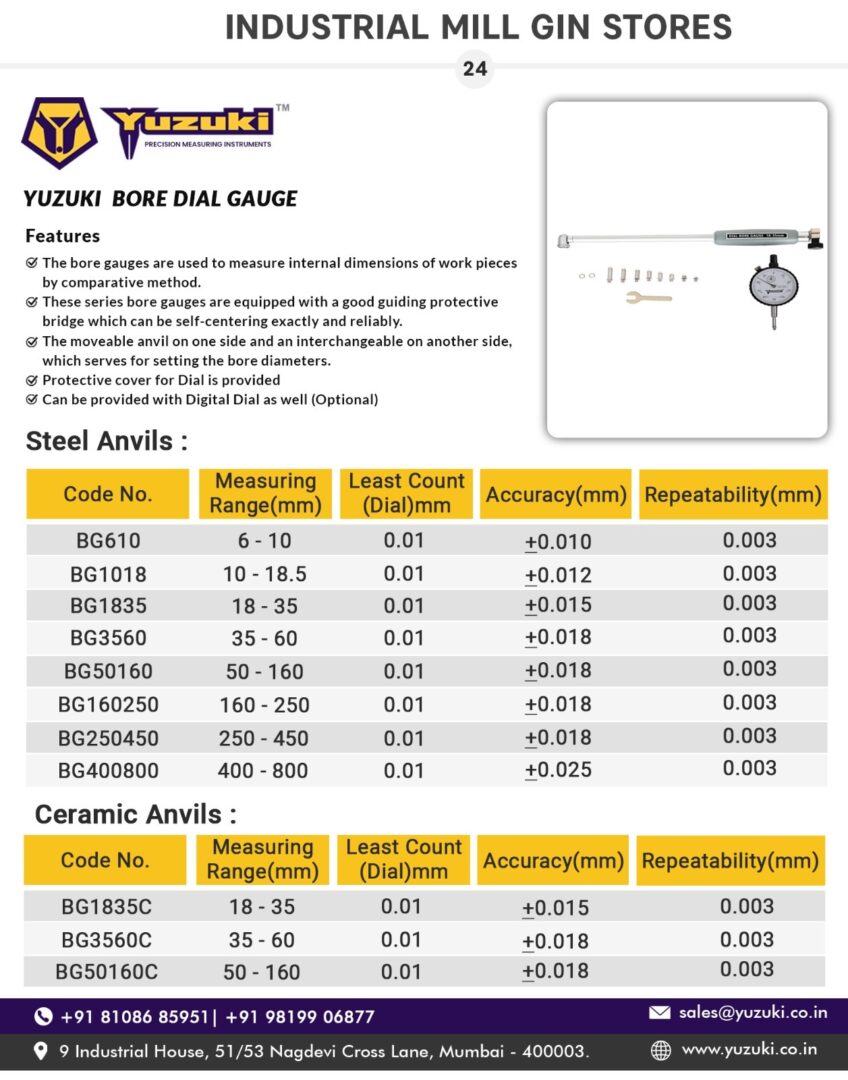

| Range | 6-10mm, 10-18mm, 18-35mm, 18-35mm with ceramic anvils, 35-60mm, 35-60mm with ceramic anvils, 50-160mm, 50-160mm with ceramic anvils, 160-250mm, 250-450mm, 400-800mm |

Yuzuki® Bore Gauges with Dial

₹4,305 – ₹12,442

Product Features

- Accurate Measurement: Precisely measures the diameter, roundness, and conicity of bores.

- Spring-Loaded Shaft: Ensures consistent and accurate readings, providing stability during measurements.

- Bore Gauges: Designed to measure the internal dimensions of workpieces using the comparative method.

- Guiding Protective Bridge: Equipped with a reliable self-centering bridge for precise and consistent alignment.

- Anvils and Washers Included: Supplied as a complete set with anvils and washers, neatly packed in a fitted box for convenience.

- Moveable and Interchangeable Anvil: One side features a moveable anvil, while the other side has an interchangeable one for easy bore diameter setting.

- Protective Cover: The included durable protective cover shields the dial for added protection.

- Optional Digital Dial: Can be provided with a digital dial for advanced measurements (optional).

Experience precision with the YUZUKI® Bore Gauges, your reliable solution for accurate internal diameter measurements. Perfect for professionals in engineering and machining, these gauges ensure dependable calibration, inspection, and quality control. Designed for durability and ease of use, they excel in automotive, industrial, and manufacturing applications. Trust YUZUKI® for tools that deliver accuracy and performance. Enquire or purchase today to enhance your measurement capabilities!

Download Catalog

View Catalog

Access the Complete Collection Catalog from YUZUKI®

View Complete Catalog

Product Details

The Bore Gauge with Dial is a precision measuring tool designed for accurately measuring the internal diameter, roundness, and overall condition of bores. Featuring a dial indicator, it provides clear and easy-to-read measurements, making it ideal for quality control in manufacturing and engineering environments. This tool helps ensure that holes, bores, and cylinders meet exact specifications for various applications, from automotive and aerospace to general machining.

Key Features and Benefits:

- Precise Measurement: The dial gauge provides high accuracy in measuring internal diameters, ensuring reliable results for quality assurance and precision tasks.

- Clear Dial Indicator: Easy-to-read dial allows for fast, accurate readings with minimal interpretation needed, improving efficiency in your workflow.

- Versatile Calibration: Suitable for measuring a wide range of bore sizes, this tool is ideal for various industries, including automotive, aerospace, and machining.

- Durable Construction: Built to withstand the rigors of daily use, the bore gauge features high-quality materials for long-lasting durability.

- Spring-Loaded Mechanism: The spring-loaded feature helps maintain constant contact with the surface for consistent and repeatable measurements.

- Compact and Portable: Lightweight and easy to handle, making it convenient for both handheld use and integration into measuring stations.

Applications:

- Automotive Industry: Ideal for measuring engine components such as cylinders and crankshafts, ensuring precise tolerances for optimal performance.

- Aerospace Manufacturing: Used to measure the internal diameters of various engine and structural components to ensure accuracy and safety standards.

- Machining and Metalworking: Essential for verifying the bore sizes of machine parts, pipes, and other components, ensuring they meet design specifications.

- Quality Control: Perfect for quality assurance teams to check the internal dimensions of parts during the manufacturing process, ensuring products meet rigorous standards.

- Toolmaking: Used in tool calibration and maintenance to ensure tools such as drills and reamers maintain their intended shape and size.

How to Use

Using a Bore Gauge with Dial is straightforward, but requires attention to detail to ensure accurate measurements. Follow these simple steps to get the best results:

- Prepare the Bore Gauge: Ensure the gauge is clean and free of debris. Check that the dial indicator is properly calibrated before use.

- Insert the Gauge into the Bore: Gently insert the bore gauge into the bore or hole you wish to measure. Align the tool so that the measuring probes are in contact with the inner surface of the bore.

- Adjust the Spring-Loaded Mechanism: If your bore gauge is equipped with a spring-loaded shaft, adjust the gauge to ensure the probes make light contact with the bore surface. The spring will ensure the probe remains in contact, providing accurate measurements.

- Take the Measurement: Rotate the dial indicator to check the measurement on the scale. The needle should move across the dial to show the exact diameter. For accurate readings, measure at multiple points along the bore to account for any irregularities like ovality.

- Record the Measurement: Once you have a consistent reading, record the measurement for your reference. Repeat the process if necessary, especially when measuring multiple bores or when high precision is required.

- Verify Calibration: After taking measurements, verify that the bore gauge is still properly calibrated for accuracy. Store the tool in a safe place when not in use to maintain its precision.

Tips for Best Results:

- Ensure the bore gauge is clean and well-maintained to prevent errors caused by dirt or wear on the measuring surfaces.

- Take measurements at multiple positions within the bore to account for any irregularities or wear in the bore.

- Calibrate regularly to maintain consistent accuracy and ensure high-quality measurements over time.

- Use the correct size gauge for your application to ensure that it fits well within the bore for accurate readings.

Related products

-

YUZUKI® Vernier Caliper with Fine Adjustment

₹1,700 – ₹22,500 Select options This product has multiple variants. The options may be chosen on the product page -

Yuzuki® Inside Dial Caliper Gauges (Knife Edge)

₹9,969 – ₹11,422 Select options This product has multiple variants. The options may be chosen on the product page -

Yuzuki® Digital Weld Gauge

₹4,012 Select options This product has multiple variants. The options may be chosen on the product page -

Yuzuki® Vernier Depth Gauge Caliper

₹991 – ₹13,896 Select options This product has multiple variants. The options may be chosen on the product page