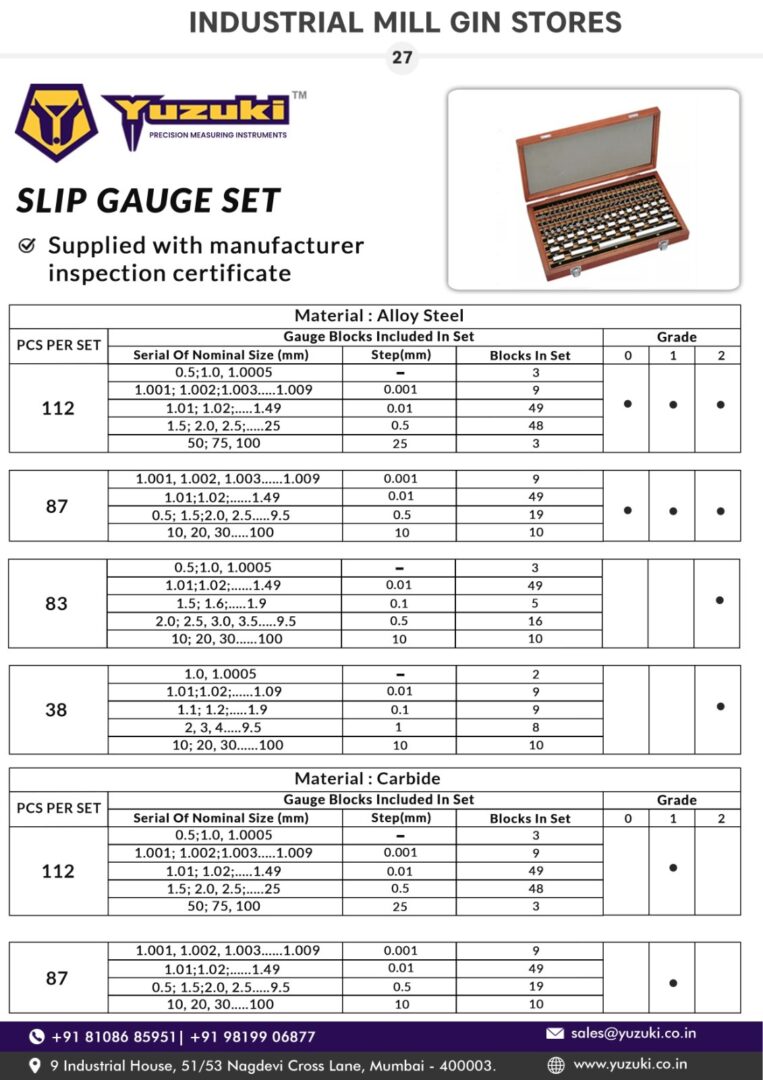

| Range | Slip Gauge Set 112 pcs ( Grade I) with Individual Calibration Certificate, Slip Gauge Set 83 pcs ( Grade II) with Individual Calibration Certificate, Slip Gauge Set 38 pcs ( Grade II) with Individual Calibration Certificate, Slip Gauge Set 87 pcs ( Grade II) with Individual Calibration Certificate, Slip Gauge Set 112 pcs ( Grade II) with Individual Calibration Certificate, Slip Gauge Set 87 pcs ( Grade I) with Individual Calibration Certificate, Slip Gauge Set 87 pcs ( Grade 1) CARBIDE with Individual Calibration Certificate, Slip Gauge Set 112 pcs ( Grade 1) CARBIDE with Individual Calibration Certificate, Slip Gauge Set 87 pcs ( Grade 0) with Individual Calibration Certificate, Slip Gauge Set 112 pcs ( Grade 0) with Individual Calibration Certificate |

|---|---|

| Brands | Yuzuki |

Yuzuki® Slip Gauge Set

₹8,100 – ₹143,500

Product Features

- Purpose: Designed for setting and calibrating fixtures and precision instruments.

- Precision Manufacturing: Produced under carefully controlled conditions to ensure the highest accuracy at a standard temperature of 68°F (20°C).

- Certification: Each gauge block set is assigned a serial number and comes with a manufacturer inspection certificate listing deviations for each block.

- Compliance: Meets or exceeds federal specification GGG-G-15C for reliability and quality.

- Durability: Manufactured to resist corrosion and defacement, ensuring long-term usability.

- Thermal Stability: Coefficient of thermal expansion is 6.4 x 10, ensuring stability under varying conditions.

- Inspection Certificate Included: Supplied with a manufacturer inspection certificate for added assurance.

Experience precision with the YUZUKI® Slip Gauge Set, perfect for calibration, inspection, and tool setting. Crafted for reliability, it features durable gauge blocks with seamless wringing for accurate measurements. Ideal for engineers and machinists, this essential tool enhances quality control and machining tasks. Visit now to explore, enquire, or purchase the YUZUKI® Slip Gauge Set today!

Download Catalog

View Catalog

Access the Complete Collection Catalog from YUZUKI®

View Complete Catalog

Product Details

A Slip Gauge Set—also known as gauge blocks or Johannson gauges—is a precision measurement tool that consists of a set of metal or ceramic blocks with highly accurate dimensions. These gauges are commonly used to calibrate measurement equipment, verify machine tool setups, and measure gaps or dimensions with extreme accuracy. Each block in the set is finely crafted to a specific dimension and can be stacked or “wrung” together to create custom lengths. This versatile tool is essential for achieving and maintaining accurate measurements in industries where precision is paramount, such as manufacturing, engineering, and quality control.

| Slip Gauge Set | Grade | Calibration Certificate |

|---|---|---|

| Slip Gauge Set 122 pcs | Grade I (Steel) | With Individual Calibration Certificate |

| Slip Gauge Set 122 pcs | Grade I (Carbide) | With Individual Calibration Certificate |

| Slip Gauge Set 122 pcs | Grade I (Steel) | With Individual Calibration Certificate |

| Slip Gauge Set 122 pcs | Grade I (Carbide) | With Individual Calibration Certificate |

| Slip Gauge Set 112 pcs | Grade II | With Individual Calibration Certificate |

| Slip Gauge Set 112 pcs | Grade I | With Individual Calibration Certificate |

| Slip Gauge Set 112 pcs | Grade I (Carbide) | With Individual Calibration Certificate |

| Slip Gauge Set 112 pcs | Grade 0 | With Individual Calibration Certificate |

| Slip Gauge Set 87 pcs | Grade II | With Individual Calibration Certificate |

| Slip Gauge Set 87 pcs | Grade I | With Individual Calibration Certificate |

| Slip Gauge Set 87 pcs | Grade I (Carbide) | With Individual Calibration Certificate |

| Slip Gauge Set 87 pcs | Grade 0 | With Individual Calibration Certificate |

| Slip Gauge Set 83 pcs | Grade II | With Individual Calibration Certificate |

| Slip Gauge Set 38 pcs | Grade II | With Individual Calibration Certificate |

Key Features and Benefits

- High Precision and Accuracy: Slip gauge sets offer exceptionally accurate measurements down to microns, making them ideal for calibration and precision tasks.

- Quality Materials: Made from hardened steel, ceramic, or other durable materials, slip gauges are designed to resist wear and deformation, ensuring longevity and reliability in rigorous applications.

- Wringing Capability: The surfaces of the gauge blocks are polished to a mirror finish, allowing them to adhere together through molecular attraction, known as “wringing,” without the need for clamps or fasteners.

- Custom Measurement Combinations: Slip gauges can be stacked to create virtually any length or height, providing a wide range of measurement options with a single set.

- Easy Calibration and Adjustment: Ideal for calibrating measuring instruments, machine tools, and inspection equipment to ensure consistent accuracy.

- Wide Range of Sizes: Available in sets with various block sizes to accommodate a wide range of measurement needs.

Applications

Slip gauge sets are versatile tools widely used across various industries and applications:

- Manufacturing and Engineering: Essential for setting up machine tools, verifying product dimensions, and conducting quality control inspections to ensure precision in production.

- Calibration of Measurement Equipment: Used to calibrate calipers, micrometers, height gauges, and other measuring instruments, ensuring they provide accurate readings.

- Inspection and Quality Control: Slip gauges help in verifying tolerances and measurements to ensure components meet strict quality standards.

- Metrology and Research: Often utilized in laboratories and research facilities where precise measurements are critical for experimentation and data collection.

A Slip Gauge Set is an indispensable tool for professionals seeking consistent accuracy and quality in precision measurements. Its durability, precision, and flexibility make it a valuable investment for any workshop, laboratory, or manufacturing facility.

How to Use

Slip gauge sets, also known as gauge blocks, are precision tools essential for accurate measurements and calibration in industrial and laboratory settings. Here’s a detailed guide on how to effectively use a slip gauge set to achieve the best results in your projects.

Step-by-Step Instructions

- Prepare the Slip Gauges

- Clean the gauge blocks with a soft cloth to remove any dust, dirt, or oil that could affect accuracy. Use a specialized cleaner if necessary, as clean surfaces are essential for accurate measurements and proper “wringing” (adhering gauge blocks together).

- Select the Desired Gauge Blocks

- Refer to the required measurement or dimension, and select the appropriate gauge blocks from the set to achieve the closest possible measurement. Slip gauges come in various standard sizes, so you may need to combine multiple blocks to create the desired length.

- Wring the Gauges Together

- Slip gauges are designed to adhere together without any external fastening due to molecular attraction. To “wring” them together, gently slide and rotate one block against another until they naturally stick together. This wringing process should be done carefully to prevent damage and ensure accuracy.

- Measure or Calibrate the Object

- Position the wrung gauge blocks against the item or equipment you’re measuring or calibrating. Slip gauges are often used to set up measurement instruments like micrometers, calipers, or height gauges to precise dimensions.

- Check and Record Measurements

- Confirm the measurement achieved with the gauge blocks and record the result. In calibration, the slip gauges provide a reference dimension, so ensure they match the tolerance or specifications required for the instrument being calibrated.

- Disassemble and Store Properly

- After use, gently separate the blocks by sliding them apart. Clean each block again and store them in their protective case to prevent wear or damage, maintaining their accuracy over time.

Tips for Accurate Use

- Handle Carefully: Slip gauges are precision instruments, so handle them with care to avoid scratching or dropping, which could affect their accuracy.

- Maintain a Clean Surface: Dirt or oil can interfere with wringing, so ensure surfaces are thoroughly clean.

- Use in Controlled Environments: Temperature variations can affect measurements. For the most accurate results, use slip gauges in a temperature-controlled environment, ideally around 20°C (68°F).

Related products

-

Yuzuki® Digital Indicator

₹1,690 – ₹18,974 Select options This product has multiple variants. The options may be chosen on the product page -

Yuzuki® Inside Dial Caliper Gauges (Round Edge)

₹6,339 – ₹12,162 Select options This product has multiple variants. The options may be chosen on the product page -

Yuzuki® Goniometer

₹1,800 – ₹2,070 Select options This product has multiple variants. The options may be chosen on the product page